Convergentia – more clever antenna solutions

The antenna design company combining antenna theory with productization experience gives you the ultimate antenna solution.

An accelerated device creation cycle and high product quality guarantee customer satisfaction.

Complementary Services

Mechanics

Antenna design company benefits hugely having a mechanics team. Our mechanics team can be called a concept creation team for a reason. Mechanics designer not only creates mechanics design but creates the concept together with the customer, industrial designer and antenna designer.

Industrial Design

Seamless fusion of industrial design, engineering and simulations. If you want to create a beautiful design without sacrificing the wireless performance we can give it to you.

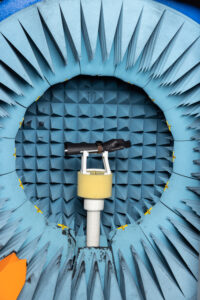

EMC

Proper EMC design guarantees that your devices function as intended and will not interfere with other devices. We are able to analyse the challenges in your design before the first prototypes are even created. Read more…

Our Commitment

Insight engineering gathers scattered pieces of data to produce a convergent, coherent design. Combining the requirements of several disciplines leads to optimal product implementation.

Together, we will unlock the full potential of your product.

Contact Us

From simple problems to complex product concepts,

contact us today!